+966 54 529 9322

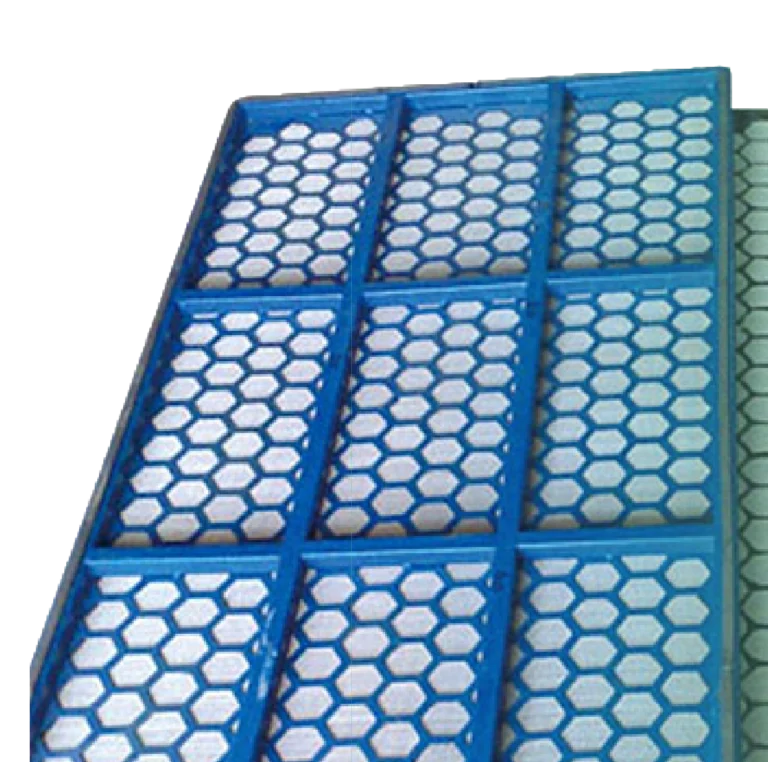

Our procedure begins with the precise selection of raw materials, focusing on corrosion resistance, mesh uniformity, and tensile strength. Using advanced manufacturing technologies—including CNC cutting, ultrasonic welding, and automated mesh alignment—we ensure that each screen is produced to exacting tolerances.

Each screen is individually barcoded and tracked through our Quality Management System (QMS), allowing for traceability, performance monitoring, and seamless integration with client maintenance records. By implementing this structured and data-driven approach, PetroSpark ensures that every screen not only performs optimally in the field but also contributes to reducing downtime, improving system efficiency, and protecting downstream equipment.

Every screen produced by PetroSpark is assigned a unique identification code, which is integrated into our centralized Quality Management System (QMS). This code tracks the screen’s production batch, material origin, and inspection history, ensuring full traceability. Upon request, we provide quality certificates, inspection reports, and compliance documentation that align with international standards such as ISO and API. This level of transparency and control gives our clients the confidence that every unit delivered has been thoroughly verified and approved.

Our Screen Quality Procedure isn’t static—it evolves. Through routine audits, feedback from field operators, and post-deployment performance monitoring, we continuously refine our manufacturing and inspection protocols. This adaptive approach allows PetroSpark to proactively address challenges, enhance screen design, and implement the latest advancements in materials and technology. By aligning our production with real-world requirements, we ensure our filtration solutions remain at the forefront of reliability, durability, and operational excellence.